LCD Connection Types

There are three primary methods to connect the LCD with its control circuitry.

Elastomers (Zebra Strips)

Elastomers are silicon strips of alternating conductors and insulators. These materials are generally soft and compliant and can be easily compressed between the Liquid Crystal Display and circuit board. Elastomers require a bezel to squeeze the display and circuit board together. This method will yield a higher conductor interconnection than pins, potentially less costly than pins, but requires a specialized compression bezel.

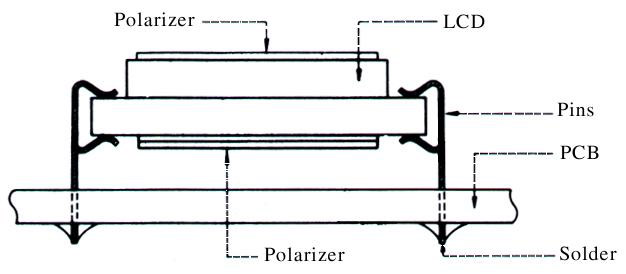

Pins

Pins are attached to the display to allow the user to either mount the display in a socket or solder it directly into a circuit board. From an end user standpoint, pins are the easiest to use since there is no requirement for a compression bezel or expensive heat seal bonding equipment.

The pins are attached to the glass with a structural epoxy on the back. On the top, we apply an electrically conductive epoxy with an RTV overcoating. Pins are the most reliable connection method, they are also the easiest to deal with for prototyping and smaller production runs. However, of all three methods, they have the lowest number of interconnects per inch.

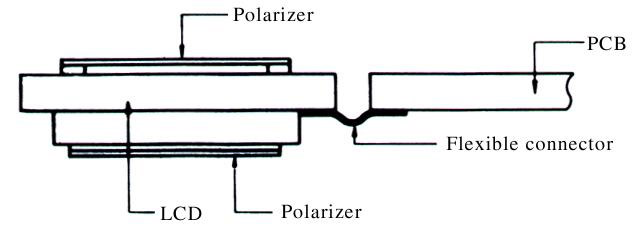

Heat Seals

Heat seals are similar to flexible circuit boards with the difference being that the interface tabs are made of a conductive hot melt adhesive. Generally, particles such as carbon, gold, or silver are added to the adhesive to make it conductive. The pads of the heat seal are aligned with the pads of the display and a hot bar is brought down under pressure and the conductive adhesive is melted and bonded to the display. The adhesive is allowed to cool and an electrical bond is made with the display. This method is the most cost effective for the higher volume applications, but due to the expensive setup and equipment required in this process, Heat Seals are typically not used for lower volume / low interconnection density requirements.

Other Types of Connection

FPC (Flexible Print Circuit) is a circuit substrate of patterning Cu electrode with Polyimide film as a base. Usually offers more flexibility than Flexible Flat Cables.

FFC (Flexible Flat Cable) is a cable with two smooth or corrugated, but essentially flat, surfaces. Attached to the PCB by soldering or plugging into a zero insertion force connector. Very reliable.

- Pre:LCD Backlighting 2018/11/20

- Next:LCD Viewing Angle 2018/11/20